Using an alcohol mixture, researchers modified how ink droplets dry, enabling cheap industrial-scale printing of electronic devices at unprecedented scales.

Have you ever spilled your coffee on your desk? You may then have observed one of the most puzzling phenomena of fluid mechanics – the coffee ring effect. This effect has hindered the industrial deployment of functional inks with graphene, 2D materials and nanoparticles because it makes printed electronic devices behave irregularly. Now, after studying this process for years, a team of researchers have created a new family of inks that overcomes this problem, enabling the fabrication of new electronics such as sensors, light detectors, batteries and solar cells.

Coffee rings form because the liquid evaporates quicker at the edges, causing an accumulation of solid particles that results in the characteristic dark ring. Inks behave like coffee – particles in the ink accumulate around the edges creating irregular shapes and uneven surfaces, especially when printing on hard surfaces like silicon wafers or plastics.

Researchers, led by Dr Tawfique Hasan (Cambridge Graphene Centre, University of Cambridge) with Professors Colin Bain (Durham University) and Meng Zhang (Beihang University), studied the physics of ink droplets combining particle tracking in high-speed micro-photography, fluid mechanics, and different combinations of solvents.

The natural form of ink droplets is spherical – however, because of their composition, our ink droplets adopt pancake shapes."

Dr Tawfiquw Hasan, (Cambridge Graphene Centre, University of Cambridge)

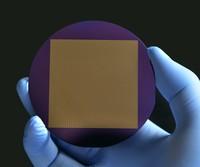

While drying, the new ink droplets deform smoothly across the surface, spreading particles consistently. Using this universal formulation, manufacturers could adopt inkjet printing as a cheap, easy-to-access strategy for fabrication. The new methodology enables reproducibility and scalability (4500 prints of almost identical devices on a silicon wafer and plastic substrate).

Click here for the Cambridge Graphene Centre article.

Click here for the Science Advances publication - "A general ink formulation of 2D crystals for wafer-scale inkjet printing."