Cambridge researchers are working to solve one of technology’s biggest puzzles: how to build next-generation batteries that could power a green revolution. The key to making electronics portable – and powering a sea change in how we communicate and consume information – was the commercialisation of lithium-ion batteries by Sony in 1991. Lithium-ion batteries are rechargeable, so when the device is connected to a charger it restores the battery for another use.

Lithium-ion batteries have undeniable advantages, such as relatively high energy densities and long lifetimes in comparison with other batteries and means of energy storage, they can overheat or explode and are relatively expensive to produce. Additionally, their energy density is very much lower than that of petrol. This makes them unsuitable for widespread use in two major clean technologies: electric cars and grid-scale storage for solar power. A better battery could make all the difference. So what’s holding up progress?

Professor Clare Grey, one of the UK’s leading battery researchers, heads a large research group in Cambridge’s Department of Chemistry. Using methods, which include NMR spectroscopy, her group (The Grey Group) studies materials that could be used in next-generation batteries, fuel cells and supercapacitors.

While Grey works with industrial partners to improve the batteries going into electric cars today, she says the role of universities is to think about entirely new types of batteries, such as the ones she is developing in her lab.

“Universities need to be coming up with answers for ten to 15 years from now – we’re the ones who are best placed to innovate, think creatively and generate radical, new solutions,” she says. “We want to make sure that our work has an impact well beyond today’s batteries.”

“When you think about other electronic devices, you’re generally only thinking about one material, which is silicon,” says Dr Siân Dutton at the Department of Physics, and who is also working on the Faraday Institution project. “But batteries are much more complex because you’ve got multiple materials to work with, plus all the packaging, and you’ve got to think about how all these components interact with each other and with whatever device you’re putting the battery into.”

click here to read the full University of Cambridge article.

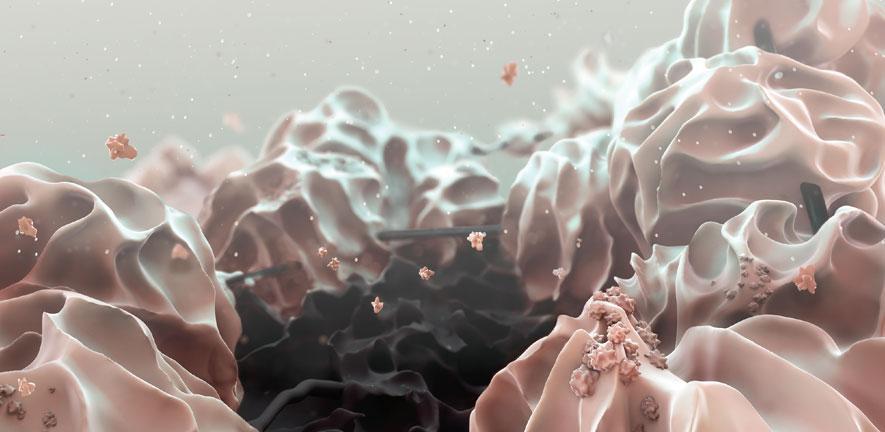

Image credit: From the October 30 2015 cover of Science. Illustration: Valerie Altounian/Science. Reprinted with permission from AAAS